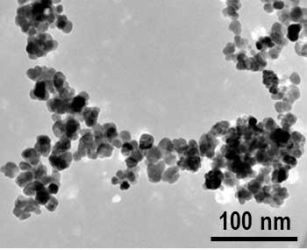

Research activities at the Center for Materials and Metallurgy – CMM include the synthesis, testing, and application of micro- and nanostructured materials with pre-defined functional properties, as well as composites with a polymer or metal matrix, sintered and biodegradable materials, and multicomponent metallic systems.

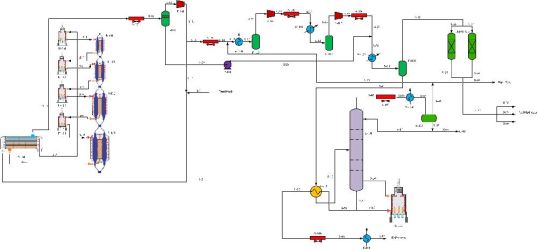

Within the concept of increasing energy efficiency and environmental protection, these materials find application as friction materials, electrical contacts, sensor elements, catalysts, and as advanced components of membrane systems for separation (membranes, separators, extraction solutions). Scientific research also includes the development of laboratory plants for filtration, reverse and forward osmosis, and recycling of organic solvents (paints), modeling and simulation of chemical processes in various industrial branches to increase energy efficiency, development and implementation of an organic Rankine cycle for generating electricity from waste heat, and energy integration of various renewable energy sources.

CMM researchers have many years of experience in the field of high-energy nanostructured magnetic materials of the Sm-Co and Nd-Fe-B type, as well as soft magnetic materials based on mixed Fe oxides, and offer product development services in the form of polymer-bonded and sintered magnets, micro- or nanoparticulate powders.

Within CMM, the long-standing tradition of research and development in the field of powder metallurgy and sintered composite materials continues and is improved. Previous generations of CMM associates were among the first in our country to start this work, and on the basis of their own human and material resources, they developed various technologies that were implemented within small-series and industrial production.

The acquired technological production processes and developed materials include: sintered composite friction materials for braking elements and torque transmission based on Fe and Cu for application in aviation, heavy transport, construction, and agricultural machinery; electrical contacts based on Ag for application in rail vehicles, drives, and work machines; special multicomponent alloys with a defined melting point for fusible safety plugs in the aviation industry and other applications.